Welding & Bonding

At RTC Engineering's Welding & Bonding Division, we offer a comprehensive range of services encompassing various types of welding and bonding operations. Additionally, we provide a full spectrum of both Destructive and Non-Destructive Testing (NDT).

In terms of welding quality, our organization is certified in accordance with EN 3834-2 and EN 15 085-2 standards.

Our expert team is not only experienced but also well-trained and fully certified in the following areas:

-

IWE: International Welding Engineering

-

IWT: International Welding Technologists

-

VT-2: Visual Testing Specialists

-

PT-2: Penetration Testing Specialists

-

UT-2: Ultrasonic Testing Specialists

-

Helium Leak Testing Specialists

We also offer a variety of other specialized procedures.

At RTC Engineering's Welding & Bonding Division, we offer a comprehensive range of services encompassing various types of welding and bonding operations. Additionally, we provide a full spectrum of both Destructive and Non-Destructive Testing (NDT).

In terms of welding quality, our organization is certified in accordance with EN 3834-2 and EN 15 085-2 standards.

Welding & Bonding

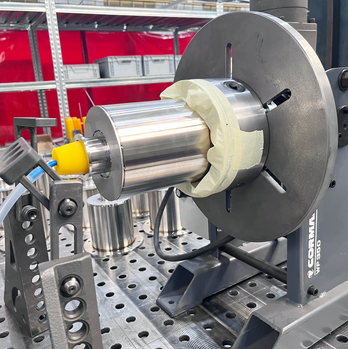

TIG Orbital Welding

Specializing in TIG welding, our company delivers precision and superior craftsmanship for all your welding needs. Leveraging advanced techniques and dedicated professionals, we ensure durable and aesthetically pleasing results for both industrial and artistic projects. Trust in our expertise to fuse quality with every weld.

-

20x Orbital welding stations

-

Expert team of internationally certified welders

-

Team of International Welding Engineer (IWE), International Welding Technologists (IWT)

-

Full NDT inspections - VT, PT, UT, Helium leak Testing, Pressure Testing

-

100% production traceability

-

Working WPQR, WPS procedures, Welding maps

-

Welding materials - Stainless steel, Aluminium, Titanium, Nickel, Mumetal, Inconel,..

-

Maximum sizes - ø 160mm x 12 000mm

Expertly versed in MIG welding, our company guarantees robust and consistent joins tailored to your specific requirements. Harnessing state-of-the-art equipment and skilled welders, we cater to a diverse range of applications, ensuring strength and durability in every project. Rely on us for top-notch MIG welding solutions that stand the test of time.

-

Expert team of internationally certified welders

-

Team of International Welding Engineer (IWE), International Welding Technologists (IWT)

-

Full NDT inspections - VT, PT, UT, Helium leak Testing, Pressure Testing

-

100% production traceability

-

Working WPQR, WPS procedures, Welding maps

-

Welding materials - Stainless steel, Aluminium, Titanium, Nickel, Mumetal, Inconel,..

-

Maximum sizes - 3000 x 3000 x 12 000 mm

MIG Welding

Specializing in TIG welding, our company delivers precision and superior craftsmanship for all your welding needs. Leveraging advanced techniques and dedicated professionals, we ensure durable and aesthetically pleasing results for both industrial and artistic projects. Trust in our expertise to fuse quality with every weld.

-

Expert team of internationally certified welders

-

Team of International Welding Engineer (IWE), International Welding Technologists (IWT)

-

Full NDT inspections - VT, PT, UT, Helium leak Testing, Pressure Testing

-

100% production traceability

-

Working WPQR, WPS procedures, Welding maps

-

Welding materials - Stainless steel, Aluminium, Titanium, Nickel, Mumetal, Inconel,..

-

Maximum sizes - 3000 x 3000 x 6000 mm

TIG Welding

Proficient in both Electron Beam Welding (EBW) and Laser Beam Welding (LBW), our company offers cutting-edge fusion solutions for precision and depth control. With a focus on minimizing distortions and achieving superior weld quality, our skilled technicians handle intricate projects across various industries. Choose us for unparalleled accuracy and strength in advanced welding technologies.

LBW (Laser Beam Welding) & EBW (Electron Beam Welding)

-

LWB description - 4kW Trumpf welding unit, welding head on Fanuc 6 axis robot, possibility of orbital welding.

-

EBW description - 2 x 35kW electron beam head, 2000 x 2000 x 3500mm size of vacuum chamber, possibility of orbital welding.

At the forefront of advanced joining techniques, our company excels in Diffusion Bonding and Brazing processes. Combining metallurgical expertise with precision equipment, we ensure seamless, high-strength bonds for diverse applications. Turn to us for reliable, state-of-the-art bonding and brazing solutions that prioritize integrity and performance.

Brazing

-

Ambient brazing & High Vacuum Brazing

-

Up to temperature - 1300 C

-

Development, Validation, Serial manufacturing

-

Sizes of 300 x 300 x 500 mm

Diffusion bonding

-

Argon environment

-

Up to temperature - 2000 C

-

Pressure - 200 MPa

-

Size - 350 x 350 x 500 mm

-

Bonding Materials - W, Mo, TZM, Ti, Grafit, Ni, Zr, Ta,...

Brazing & Diffusion Bonding

Cutting & Material Forming

Leading the way in precision material processing, our company offers top-tier laser cutting, water jet slicing, and expert pipe bending services. Utilizing the latest technology, we deliver clean, accurate cuts and perfect bends, meeting the most stringent specifications. Trust in our multifaceted expertise to reshape, cut, and transform materials with unparalleled precision and care.

Material cutting

-

Laser Cutting

-

Plasma Cutting

-

Water Jet Cutting

Material forming

-

Pipe bending

-

Press break

-

Hydraulic press

-

Hydro froming

Full service of heat and surface treatments.

-

Vacuum Hardening

-

Anodising, Pickling, Passivation

-

Glass Blasting

-

Electro & Electro Less Polishing

-

Chemical & Physical Deposition of different coating

-

Nitriding, Plasma Spraying

-

Electro & Electro Less Coating , Blacking

-

Gold, Silver, Copper Plating

-

Powder & Wet Colouring

Surface & Heat Finishes

Quality assurance

State of the art quality assurance department.

-

3 x CMM Carl Zeiss

-

Hexagon Scanning Arm

-

Full NDT inspection - VT, PT, UT, RT, Thermography,

-

Material Analysis - SEM, XRF

-

Helium Leak Testing, Pressure Testing

-

Destructive testing, Aging testing

-

Internal Calibration Laboratory

-

Complex Quality Processes

At RTC Every client has dedicate Project Engineer / Project Engineering team taking care of all related to the project and client satisfaction.

-

We use complex ERP system to ensure 100% project / part traceability

-

Production is managed by QR codes

-

Project schedules is regularly updated and reported

-

Quality processes & Inspection plans

-

Online reports

-

FMEA & Risk Analysis

-

Every operation has its training program, records, procedure